Pipe Strain

Pipe strain is defined as the misalignment of suction and discharge piping in relation to the dynamic equipment in which it is connected. All surfaces in the same plane should be within 0.002” tolerance to prevent pipe stain. This misalignment will cause stresses on the frame of pump for instance and ultimately spread to the entire body of the equipment. This often results in shaft misalignments causing seals to fail prematurely as the equipment was not designed to operate with these external forces.

Some causes to pipe strain include improper design or installation of the piping, including improper support. This can be caused by not considering piping change from the process, movement in the piping caused by temperature and pressure changes.

The piping should line up to the machinery with no external force needed to line up the flanges. For example, a chain fall should never be used to line up piping to dynamic equipment. The piping system should be designed to ensure proper support, consider effects of temperature and pressures and install expansion joints in the piping system where necessary.

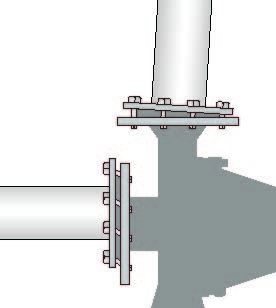

On the left are two examples of piping connected to a pump. The first shows the proper installation of the piping lining up with the flanges of the pump. The second shows some misalignment which will ultimately effect the performance and life of the pump.

To sum it up if your pump were to magically dissolve all piping connected should not move. The piping system should not exert any forces on the dynamic equipment which will affect it’s performance.